|

| Moving to the left limit and setting the clamp. |

|

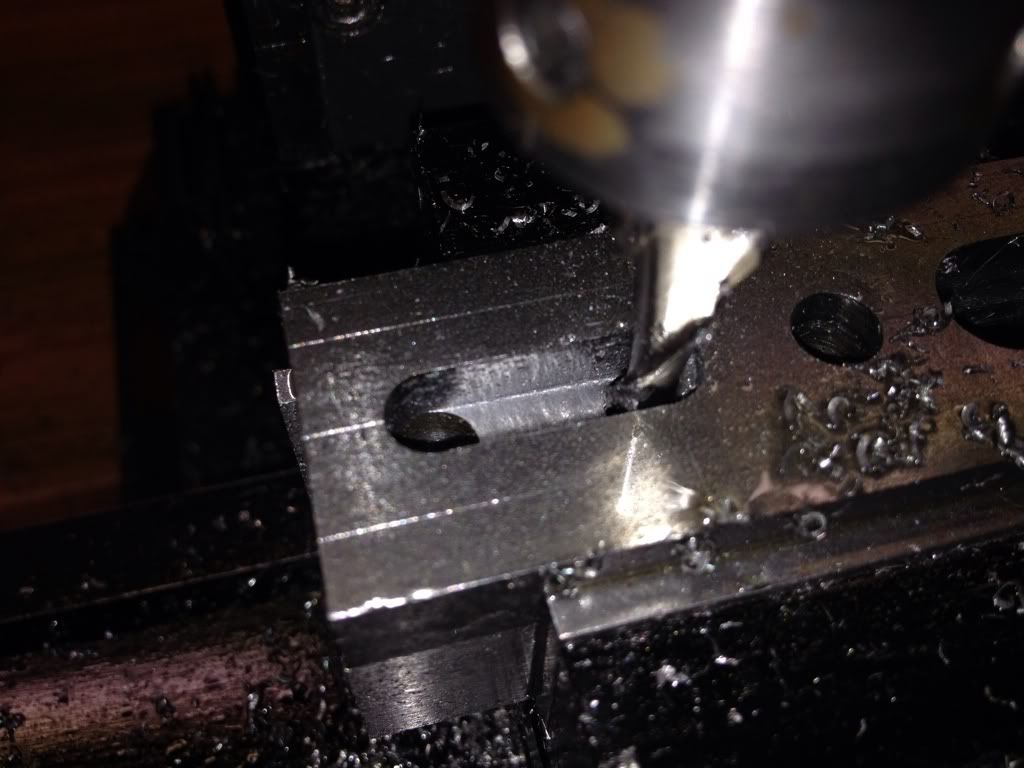

| Milling the 1/4" slot with the Sherline 1/4" slot drill. The Sherline's endmill holder in use here. |

|

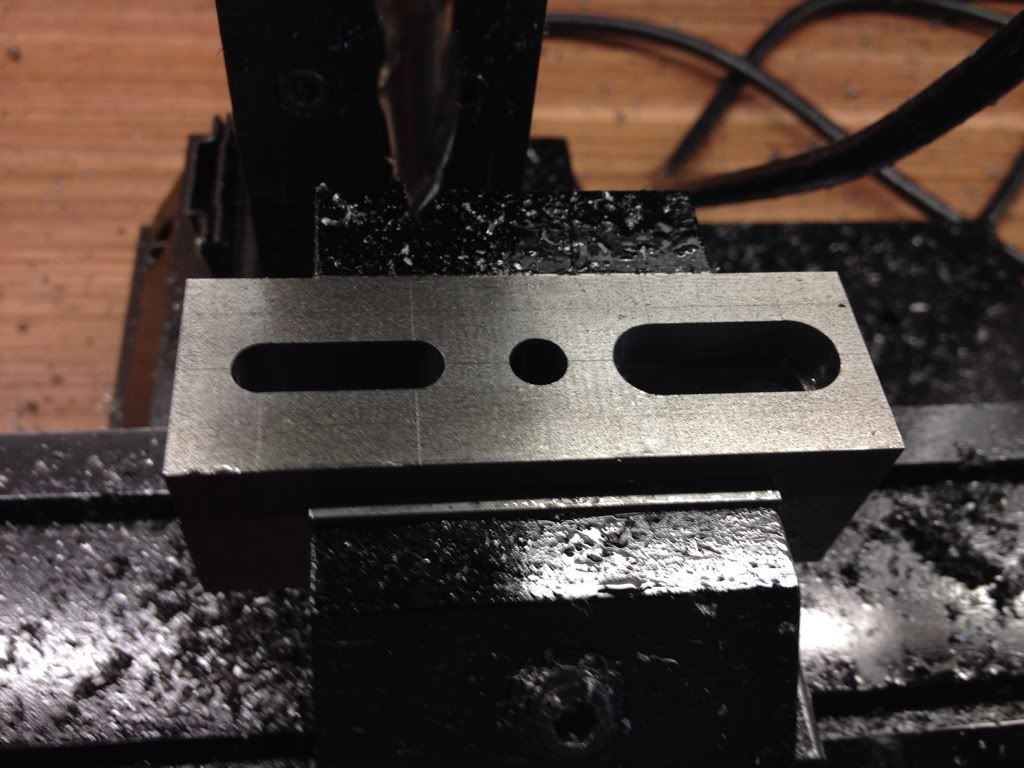

| Slot done. |

|

| Slot done. I went at 0.25mm per pass to minimise vibration. The cap screw sit flush with the top surface of the Base. |

|

| The centre hole enlarged to 6.4mm to tap 5/16" BSF. |

|

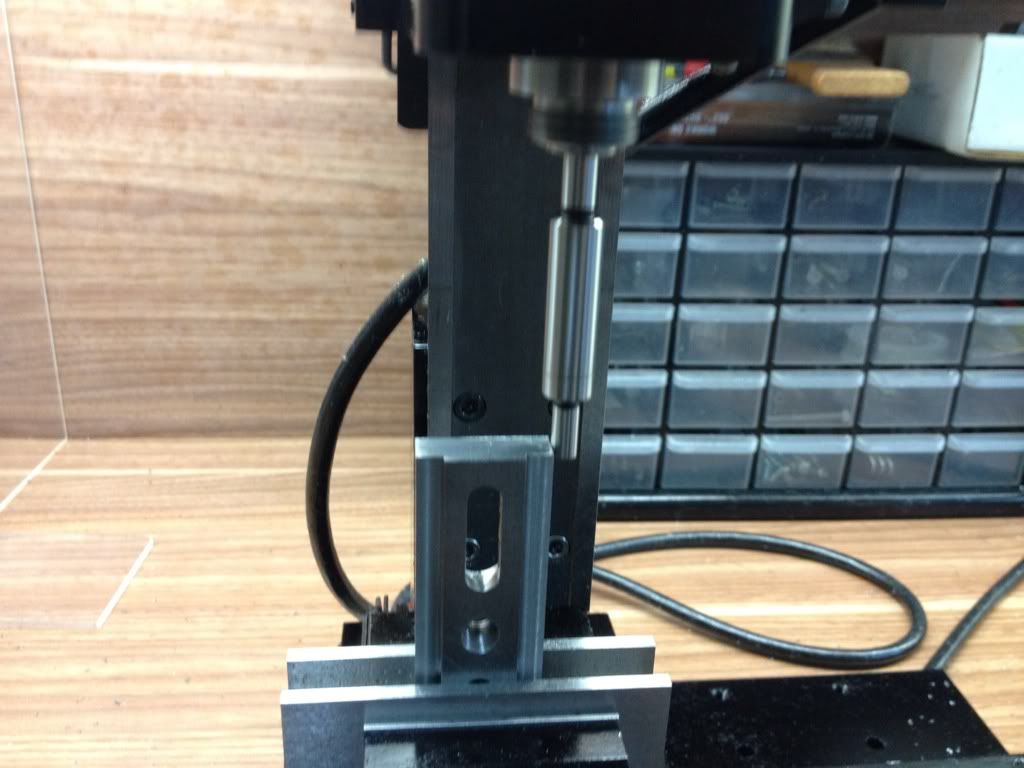

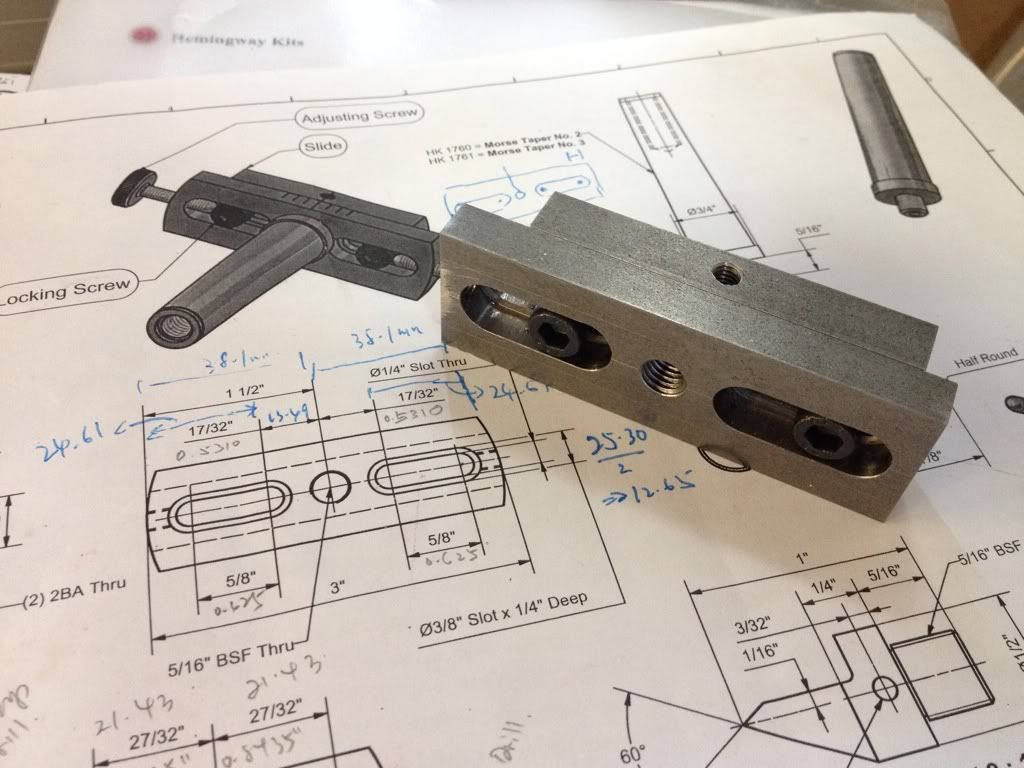

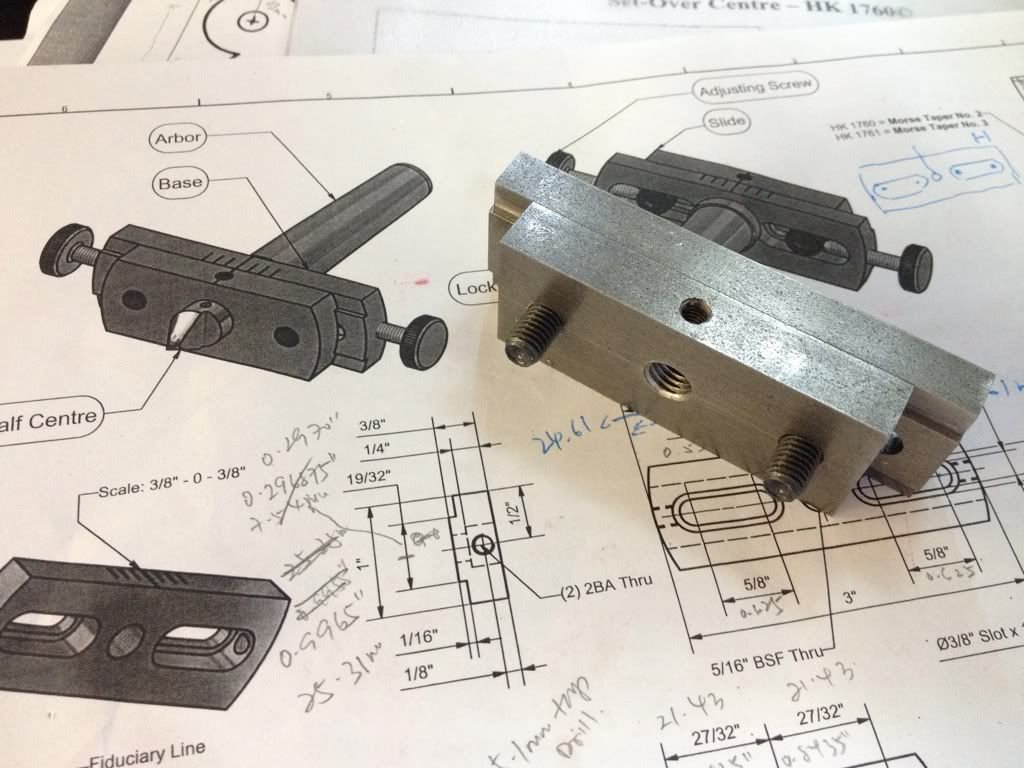

| Testing fit. No side wobbling encountered. I'm pretty pleased :) |

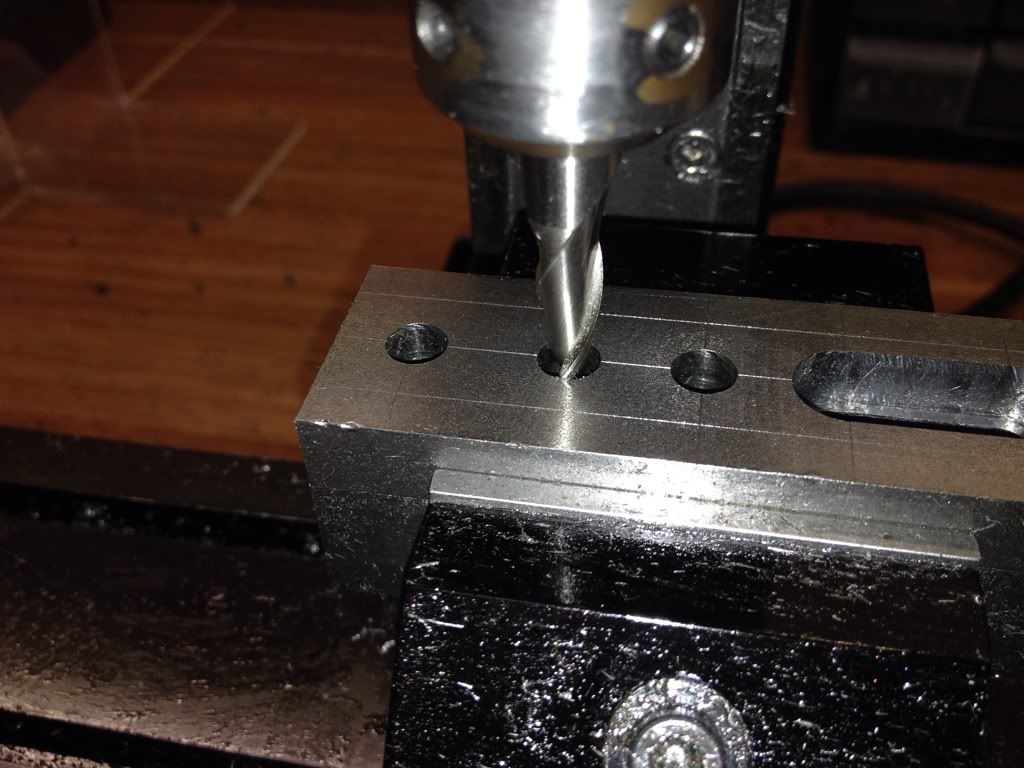

The instruction calls for the 2 x 2BA holes to be done on the drill press. I was running out of time to set up the drill press (its under the bench...) and so stand the part in the vise and carry on.

|

| Locating the side and dialed to the centre of the workpiece. |

|

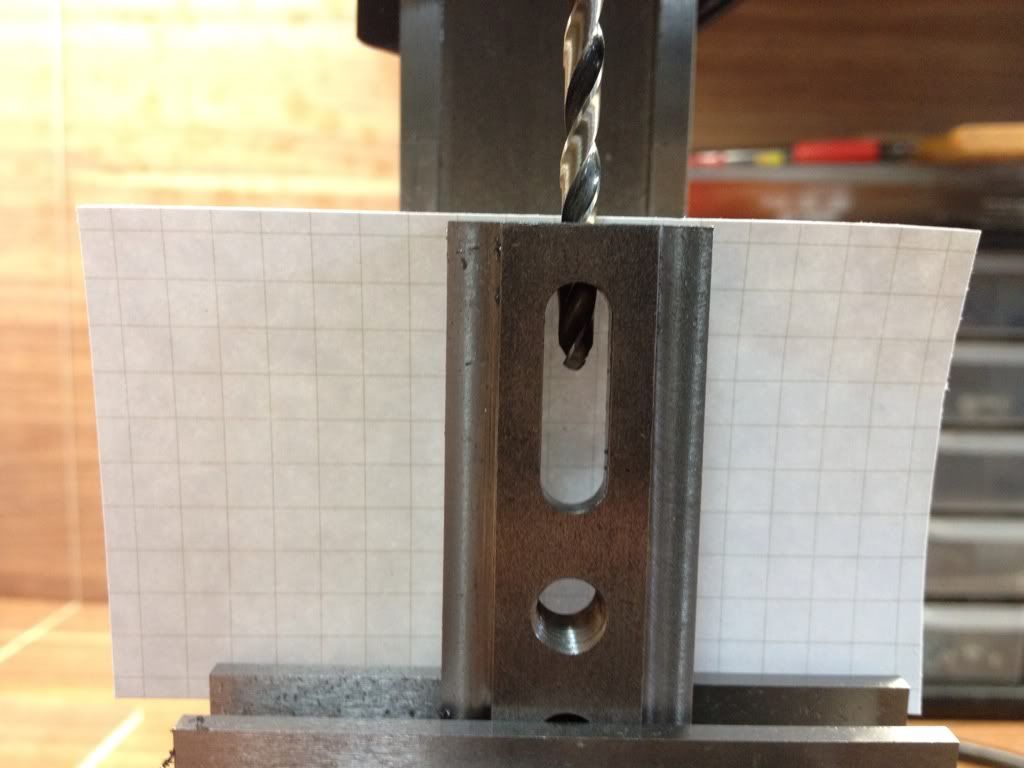

| Centre drill and drill through with a 4mm. I'm at the limit of the z travel... |

|

| A piece of card stock used at the back to check if I'm right in the middle. Not too bad.. |

The part was then flipped over to drill and tap the other 2BA hole on the other side. This completes the work on the Base.

|

| View from the back where the 2MT Arbor will be screwed in from. |

|

| The front. I'm wondering if the screws are a little too long. The drawing shows them as almost flushed with the surface. Can those who did this confirm if I need to shorten the screws? |

The rest of the work will be mostly done in the lathe. From the plan, I'm left with making the 2 adjustment screws, the Centre, and the 2MT Arbor.

I'm hoping to get back to the shop real soon!

Blessings to ALL!!!

No comments:

Post a Comment