This post is not about making the transfer screws as the set I bought is now sitting at the Post Office waiting for my collection. It is about my attempt to make the point like what was shown on Bob Warfield's website (www.cnccookbook) as shown below:

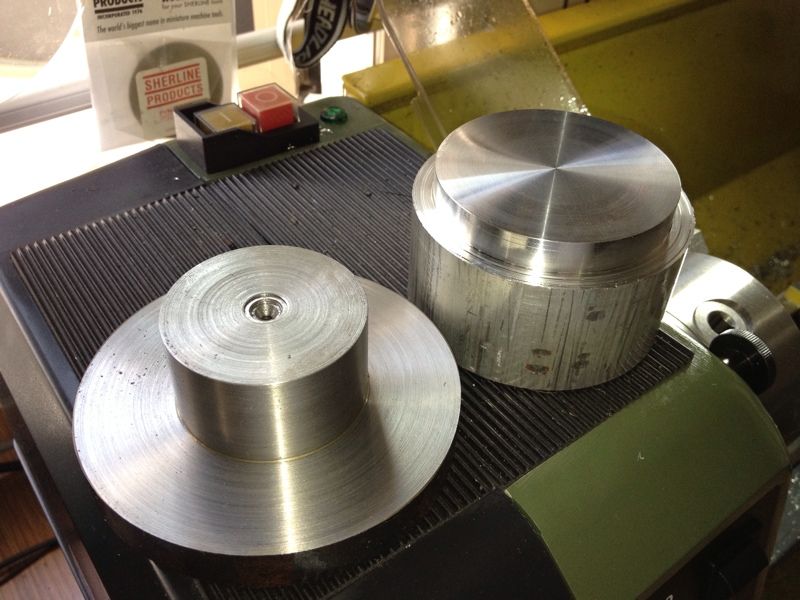

I've been wondering how he did this. What I did before was to have the base of the point (which is basically a cone) equals to the diameter of the rod or screw.

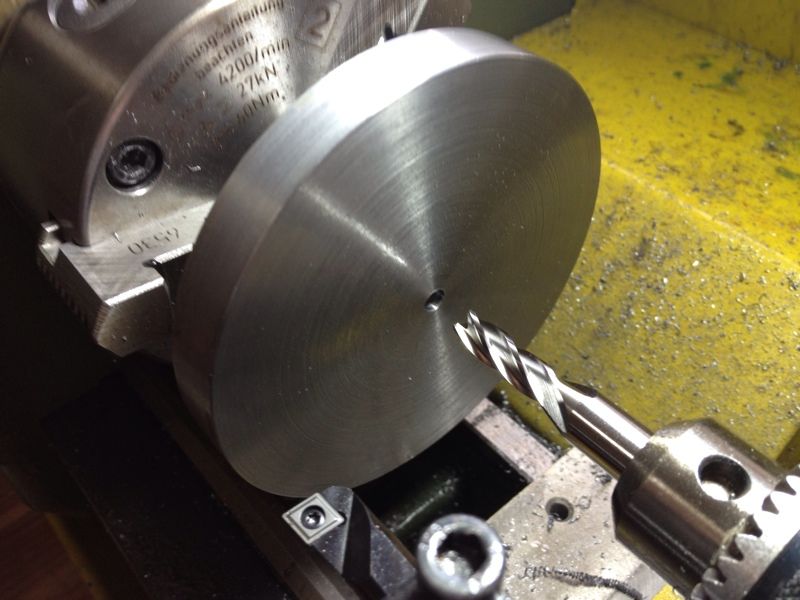

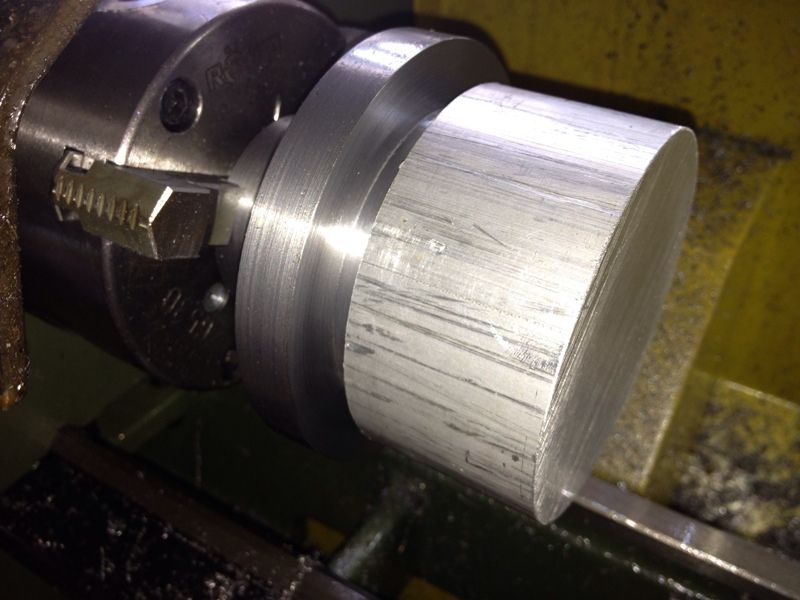

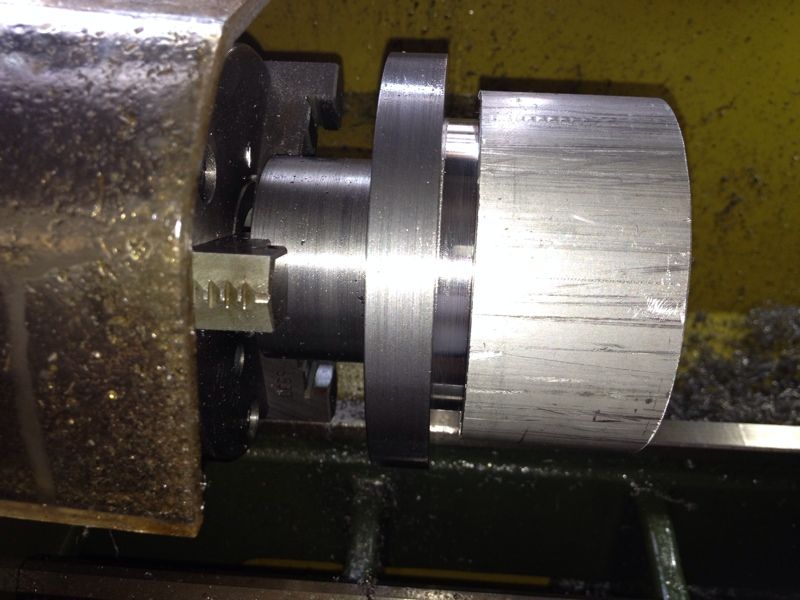

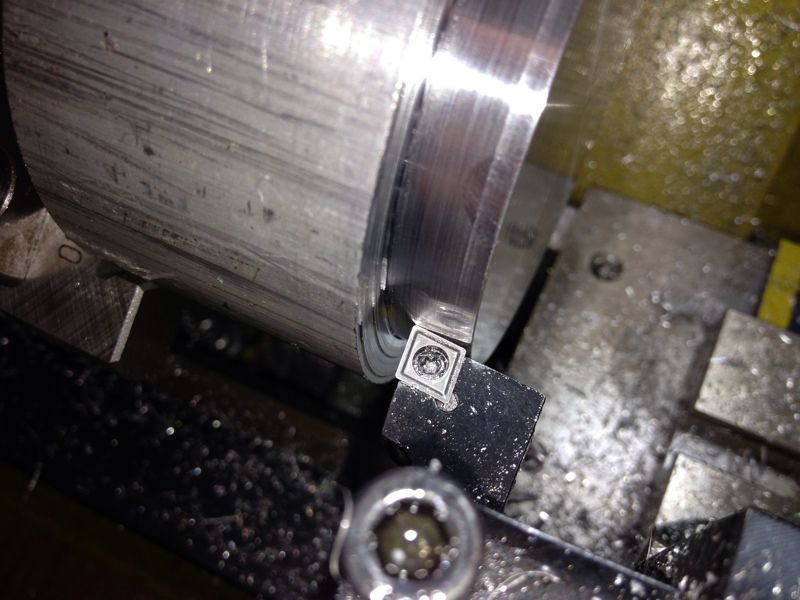

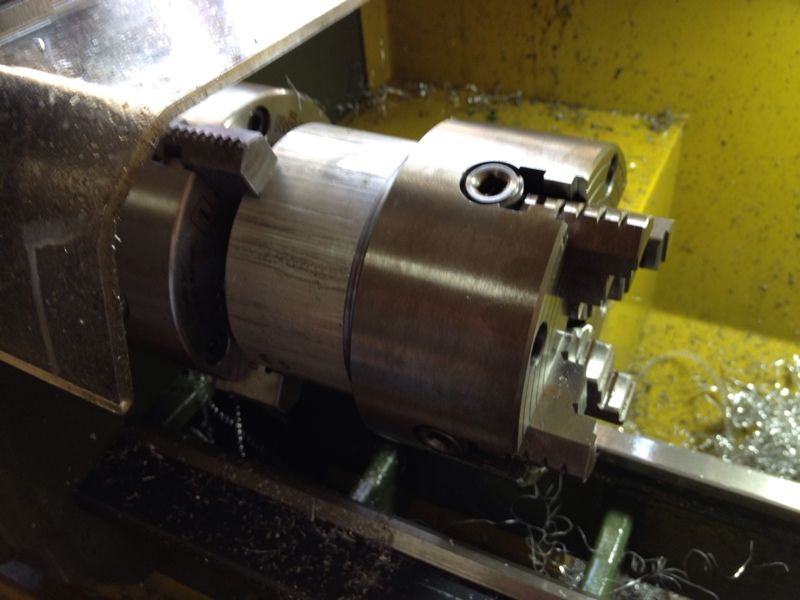

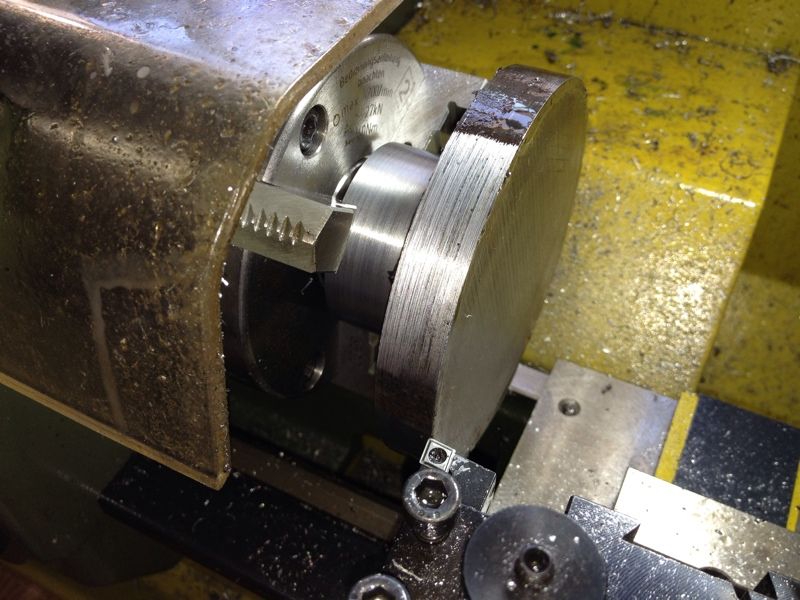

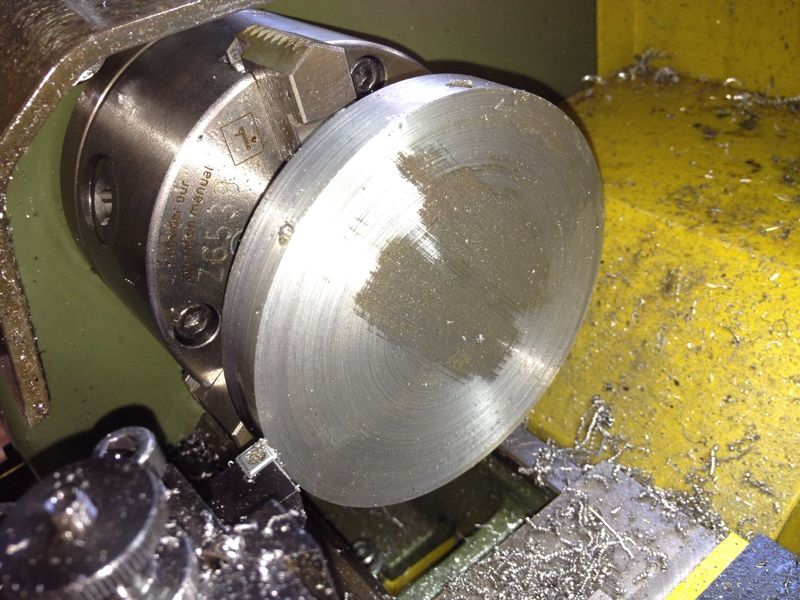

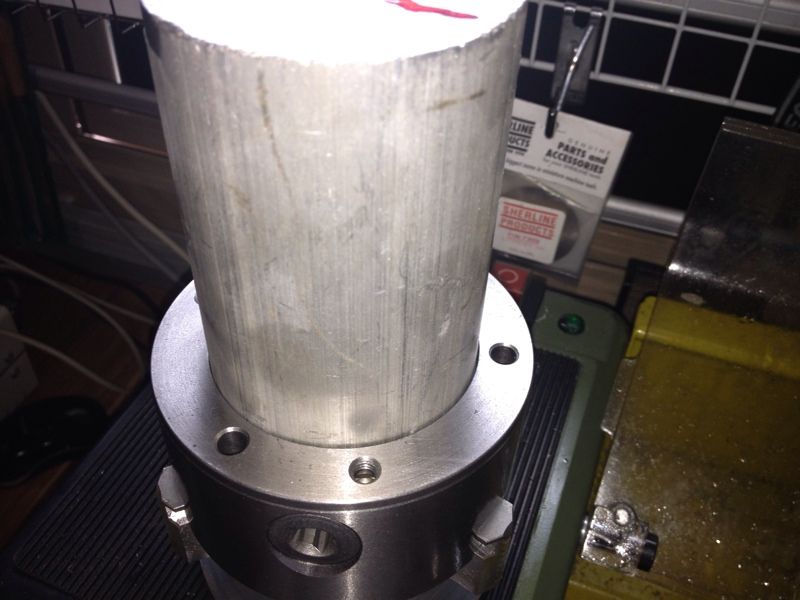

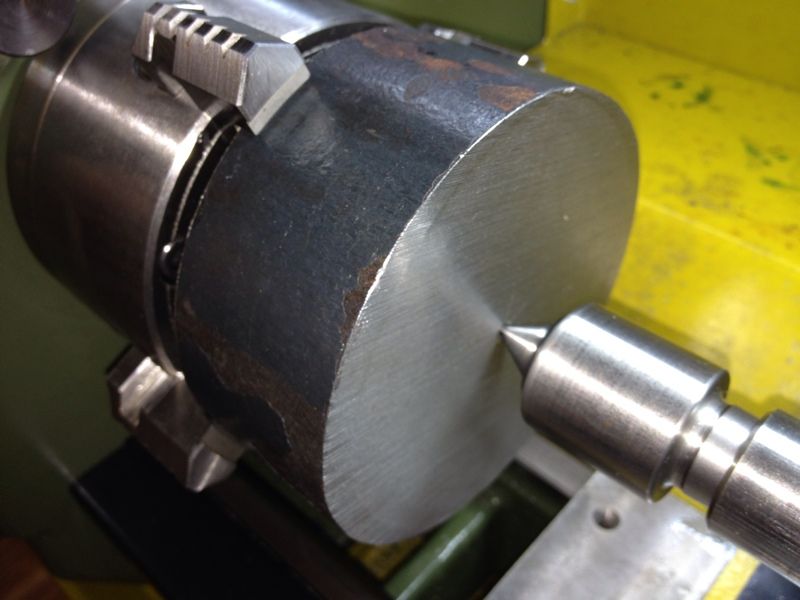

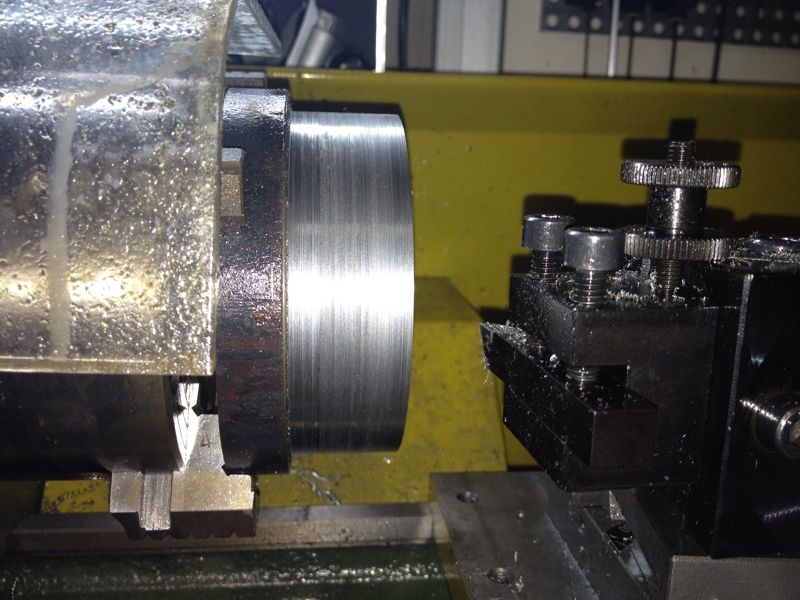

This morning, before leaving for work (I know it's Sunday and it sucks to be working on the Sabbath), I did an experiment. An M6 cap screw was mounted in the 3 jaw with its hand sawn off using a hacksaw. The top slide was turned to the 30-degree mark on the graduation and advanced to make the cut. I tried stopping at around the same Z depth and in no time, I get the result I want:

That made my day!!!

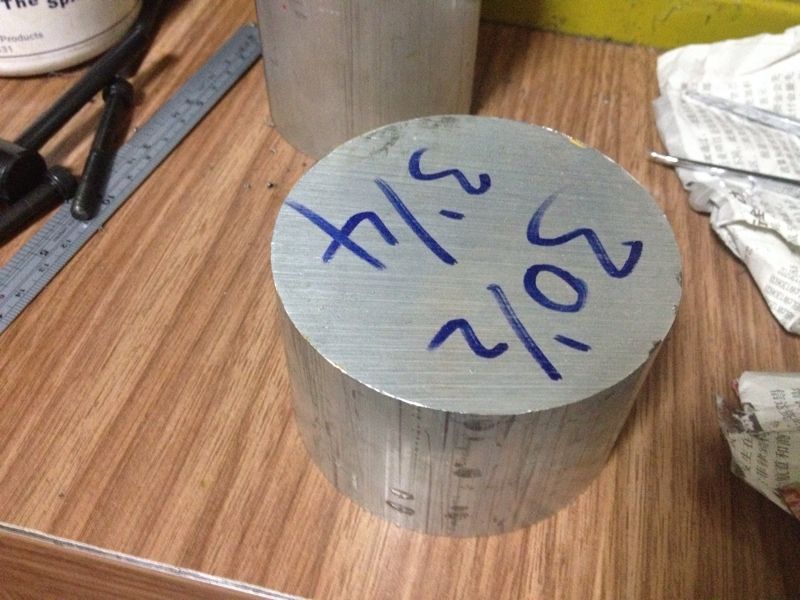

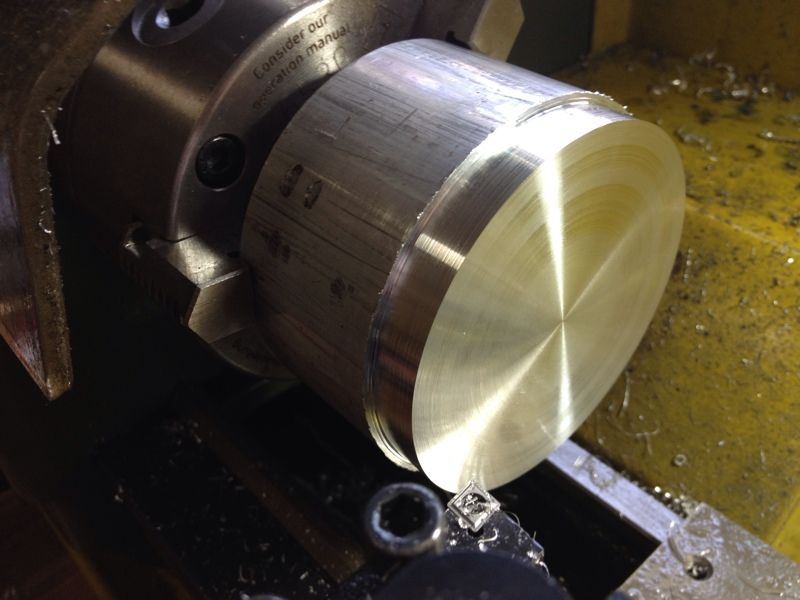

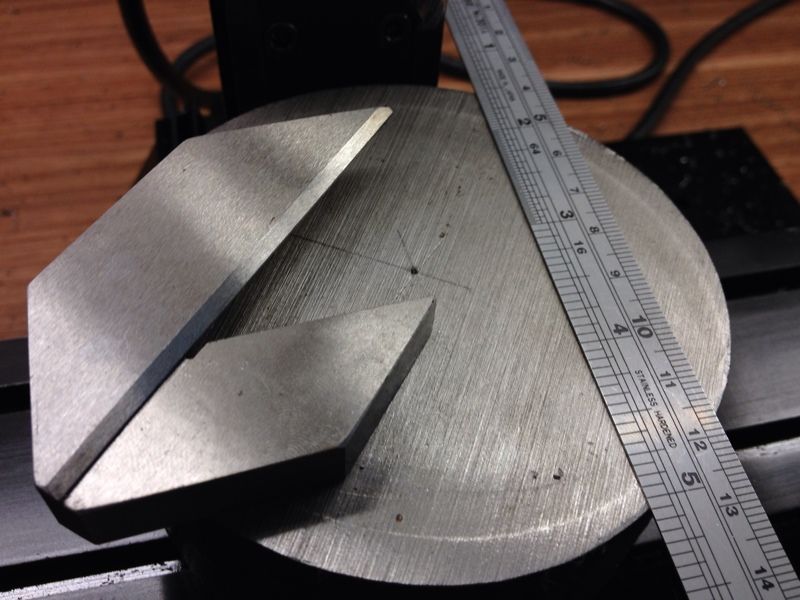

The point wasn't hardened. It works alright on aluminium but could stay sharp for a single use on steel. If you observe the pic above carefully, you'll see that the tip is a little blunt. This pic was taken after testing on both aluminium & steel.

This was when the piece just came off the lathe.

But I still leave for work happily as I now know how it is done.

- Posted using BlogPress from my iPhone