I've in my stash bin a big piece of aluminium of unknown composition, though I asked for T6061 during the purchase. I started by cutting it roughly to size using my Proxxon band saw.

This is a painfully long process on this mini band saw. But I finally get to the end of this 150mm piece.

The plywood base was added as the aluminium table that came with the band saw is a little too small for my use. It measures 200mm x 200mm only.

I made a mistake when Installing the plywood base. The grain should be along the line of cut rather than across. I'll be more careful with my next one.

The 2 long sides were then fly cut and I left the 2 shorter side till I bring the thickness of the block to the required 3/4" (19.05mm). Main reason for this is, the longest end mill I own has DOC (depth of cut) of 3/4". This was when disaster struck; the surface of the block being fly cut indicated to me that my mill is out of square.

May not be obvious from this pic but there were ridges on the surface that can felt by running your fingers over it.

This forced me to re-tram the mill again. I took the opportunity to do some general cleaning while dismantling the entire mill. This is a painful process. It took me quite a few hours to get this right. But it is an effort worth making.

Once done, I resume work with fly cutting and I'm able to get to 0.02mm in accuracy over the length of 150mm. The stock is now in its required size ready for its next operation - milling of the slot before cutting the dovetail.

Since this is my first attempt in making tool holders as well as using a dovetail cutter, I decided to cut out a small section from the stock, sufficient to make 2 holders. This is to prevent screwing up the whole piece.

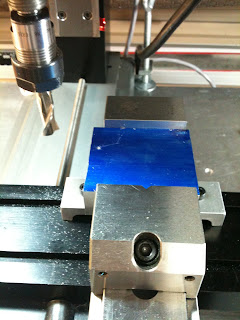

This piece is enough to make 2 holders. Ready to clean up the rough edge after sawing off on a band saw.

After some side milling to clean up the saw edge.

In my next instalment, I'll be talking about milling out the slot before cutting the dovetail.

No comments:

Post a Comment