The slides of the lathe was stripped for some generally cleaning. This time, I managed to remove the carriage which I couldn't previously. This goes to show the more I use the machine, the better I understand it. But my confident stopped right here. I'm deciding if I should disassemble the 1/2 nut for thorough cleaning and maybe attempt some adjustments to make it operates smoothly.

These are the pics taken of the apron and carriage:

|

| The lead screw has to come out first before I can remove the apron then the carriage. How silly I was before... The air compressor was used to blast away all the chips and the old grease was wiped off. |

|

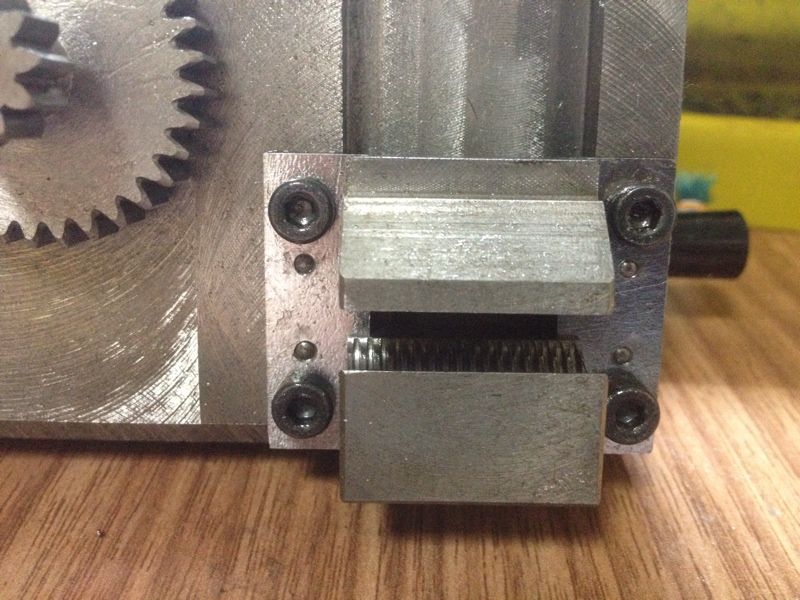

| The half nut looks easy to disassemble but I'm concern about not being able to put it back properly with the clutch at the right position. |

|

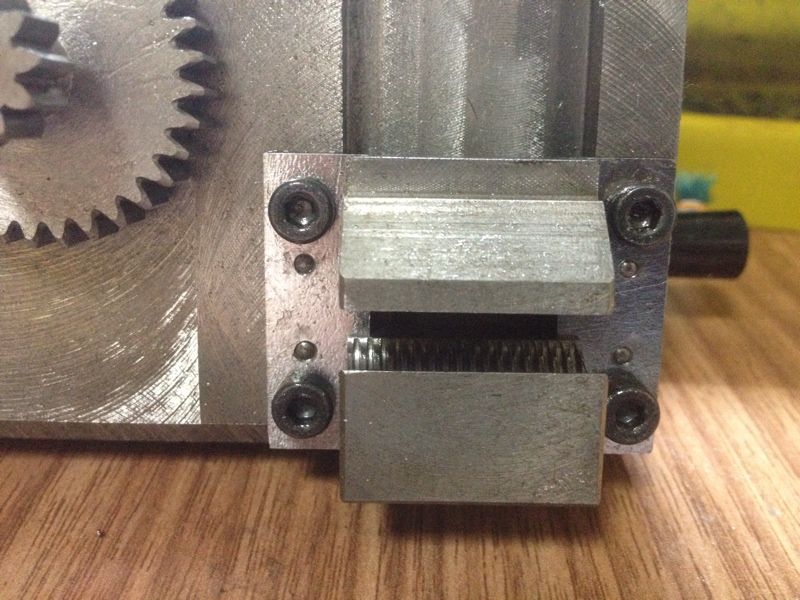

| The bottom of the carriage. The 2 cap screws and set screws were the trouble when I first tried adjusting the carriage from underneath. It is clear from this pic that the carriage lock operates only on one corner of the gib plate. I wonder if it can be easily relocated to the middle. |

|

| I took this pic to prepare for the making of the carriage stop. With pics in my iPhone, I can visualize how certain things can be implemented while I'm outside. |

So, anyone can enlightened me on the half nut adjustment?

7 comments:

Wong, go for it. The four cap screws will release the two guide plates. Maybe mark them left and right in case they aren't identical. The upper and lower half nuts are unique and can't be mixed up, just put them back as in your photograph.

In back of each half nut is a pin that engages two slots in the cam that moves them up and down.

If the guide plates and grooves in the half nuts are smooth your roughness maybe in the slots in the cam.

GeneK

Ok, guts booster taken. Was take it apart in my next session. Otherwise, I can use the lathe in its current state... Lolz...

Again Slightly off topic Wong but I have had to turn lathe over previously to snug up the carriage gib via the screws-it is not something I want to repeat on a regular basis!! I didn't even think about adjusting these nuts by removing the apron and carriage. Do you think this is an easier option when it comes to next time? I have digital slides that I have to remove before turning machine over-It's a real pain!

Hello Charlie,

Don't worry about OT as long as its machining related. I call the shots here 😜.

I managed to find a long enough extension to use with my ratchet wretch and a long enough hex key do that I don't have to flip the lathe around. A bit of a fiddling but it gets the job done. Stripping the apron and carriage for adjustments can be quite a pain unless you can hit it spot on the first time, everytime.

Regards,

Wong

Thanks Wong, great to have a forum dedicated to this machine, as you know there is not much anywhere else on the web!

In relation to your carriage issues-I had a vaguely similar problem myself:

The leadscrew handwheel being stiff to turn when leadscrew disengaged(manual)OR Jumpy/Stuttery Motion from Carriage Handwheel when leadscrew engaged (auto feed).

My problem was temporarily resolved by applying same direction of travel force to the carriage handwheel at the same time as turning leadscrew handle (manual turning) Or just applying same direction pressure to the carriage handle when using feed. Contacted Proxxon who advised I slacken off the locking nut on the carriage handwheel assuming it was too tight-In fact it needed to be tightened as there was way too much play in my instance. Played about with nut until happy with both feed and manual, applied plenty of oil at the wheel apron interface and grease on the rack and thereafter problem solved-for me anyway-hope this helps

Charlie

Thanks Charlie. It will not just be on the PF 400 but in the machines I have in my shop. When the mill comes, you'll see some shift in the attention. But I believe I'll not neglect the lathe when that happened.

I adjusted the lock nut of all the handwheels till I've it loose enough to turn smoothly but with minimum play.

I am doing the same when turning the leadscrew by applying slight pressure on Tge carriage handwheel. No problem with the auto feed though. I'm always full of envy seeing videos of folks turning their handwheels so smoothly. The reason why I'm stripping the half but is to see if there is any available adjustments I can do to make things better. Hope I don't screw it up instead.

Regards,

Wong

Hi Charlie,

Are you are able to send me some pics of lathe with the digital scales installed? I'm thinking of doing that. I've some iGaging scales on hand.

My email address: lokeyeow@wongstersproduction.com.

Thank you!

Regards,

Wong

Post a Comment